LED 灯泡或是灯管 UL认证

标准:

UL 1993, UL 8750, CSA C22.2 No. 1993-09, CSA C22.2 No.250.13.

| 电源 | LED 灯泡/灯管 |

| CLASS 2 | LED 灯珠可以不要要外壳(电源测试比LVLE 多一些) |

| LVLE | LED 灯珠可以不要要外壳 |

| non class 2 | 需要防触电、防火保护,玻璃灯泡需要做钢化处理;

或是LED 灯珠有机械的外壳隔离 |

LED 球泡灯的样品和资料要求

样品:

1,主测型号17个,6个完整样品,11个散件

2,裸板2-3块,保险丝,保险电阻大电流冲击,过载

3, 隔离变压器 散件

4,绝缘胶纸 报备需要考虑

资料需要:

1,LED型号列表,包括电气规格,电流,电压,功率,LED 厂家,参数

2, 样品差异;

3,可选: 可调光:后端、前端,安装在密闭环境?? 干燥,湿气?潮湿?

4,整体照片,散件照片,

5,外壳,散热部件/灯杯,灯头吃尺寸图;

6,电路原理图,PCB layout

7, marking 问题

8, 关键部件的CCL

9, 普通元件需要BOM表

标准结构要求, UL 1993 Scope:

1.1 These requirements are intended to cover both self-ballasted lamps and self-ballasted lamp adapters rated 120 to 347 V AC nominal for connection to screw-base, pin-base, or recessed single contact (RSC or R7) lampholders. These devices are intended for use in accordance with the National Electrical Code, ANSI/NFPA 70, and the Canadian Electrical Code, Part I, in non-hazardous locations, and the Instalaciones Elerctricas (utilizacion), NOM-001-SEDE.

1.2 These devices incorporate resistance, reactance, or electronic (solid-state) type ballasts or power supplies. These devices employ various lamp technologies including, but not limited to, incandescent, fluorescent, high-intensity discharge lamps, light-emitting diodes.

1.3 These requirements also include Supplemental Requirements for Light-Emitting Diodes (LED), Supplement SA, for:

a) Self-contained LED lamps, rated 120 to 347 V AC nominal for connection to screw-, pin-base, and recessed single contact (RSC or R7) lampholders,

b) Lamps for replacement of an ANSI standardized fluorescent lamp, and consisting of light-emitting-diode (LED) lamp technologies, with control circuitry, and a driver or power supply. The LED driver and control circuitry will be either integral with the lamp or remote from the lamp, and

c) Component LED lamps, with or without control circuitry, an ANSI base other than bases mentioned in (a), for connection to LED driver having a low voltage output, such as replacement for tungsten-halogen, MR11 and MR16 shaped lamps.

1.4 This standard does not apply to medium-to-medium base (E26) fittings that incorporate controls such as photocells, motion detectors, radio controls, or dimmers covered by other standards.

1.5 These devices are not intended for use with emergency exit fixtures or emergency exit lights.

产品外壳要求:

5.1.1 Enclosures shall have the strength and rigidity to resist the abuses to which they are subjected, without increasing the risk of fire, electric shock, or injury to persons due to a reduction of the required spacing for live parts or the loosening or displacement of live parts.

5.1.2 An enclosure shall be of metal or of a polymeric material that complies with Clause 5.3.

5.1.3 A metal enclosure shall comply with the minimum thickness specified in Table5.1.

Table 5.1

Thickness of metal enclosures

(See Clause 5.1.3)

| Metal | Minimum thickness, mm (in) | |

|---|---|---|

| Cast metal | 1.2 | (0.047) |

| Uncoated sheet steel | 0.66a | (0.026) |

| Nonferrous sheet metal | 0.81 | (0.032) |

| a Uncoated sheet steel with a minimum of 0.51 mm (0.020 in) is acceptable if the ballast part of the device is filled with potting compound. | ||

5.1.4 An enclosure constructed of iron or steel shall be protected against corrosion by plating, painting, or the equivalent on both inside and outside surfaces.

金属外壳,按照要求需要大于0.81mm

产品外壳开孔:

5.2.1 An enclosure shall not have openings wider than 2 mm (0.078 in), unless they do not permit a 2 mm (0.078 in) diameter rod of any length to contact live parts. The uninsulated live parts of a lampholder into which a lamp connects are not required to comply.

5.2.2 The enclosure openings in a lamp adapter shall be evaluated with the lamp removed.

5.2.3 A hole in an enclosure through which wires emerge to connect with a lamp connector shall be:

a) Close-fitting to the emerging lead wires,

b) Free of burrs, sharp edges, and the like, that can abrade the insulation, and

c) Provided with a strain-relief means that complies with the strain relief test for lamp connectors of Clause 8.11.

塑料外壳

5.3.1 (CAN) In Canada, a polymeric material shall comply with the requirements in CAN/CSA-C22.2 No. 0.17 and with the requirements of Clauses 5.3.2 to 5.3.4 and Clause 5.3.6 when the material is used to:

a) Enclose electrical parts,

b) Provide direct or indirect support of live parts, or

c) Both.

5.3.1 (MEX) In Mexico, the parts of insulating material that contain live parts and external parts of insulating material that provide protection against electrical shock shall be subjected to the glow-wire test in accordance with NMX-J-565/2-11-ANCE and to the following:

a) The test specimen shall be an end product. If it is necessary to take a part from the lamp in order to perform the test, care shall be taken to assure that the test conditions are not significantly different from that which occurs in normal use conditions;

b) The temperature in the tip of the glow-wire shall be 650 C.

5.3.1 (USA) In the United States, a polymeric material shall comply with the requirements for portable equipment specified in UL 746C and with the requirements of Clauses 5.3.2 to 5.3.6 when the material is used to:

a) Enclose electrical parts,

b) Provide direct or indirect support of live parts, or

c) Both.

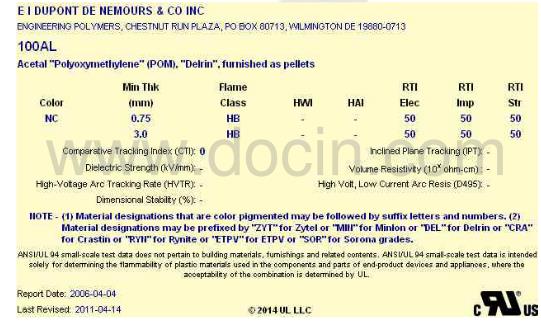

5.3.2 A polymeric material used to enclose electrical parts shall have a Relative Thermal Index (RTI), including electrical and mechanical, with impact properties of at least the temperature measured during the temperature test of Clause 8.5, unless the measured temperature is less than 65 C.

5.3.3 A polymeric material used as an enclosure shall have a flammability rating of 5-VA, 5-VB, or V-0 in accordance with UL 94 or CAN/CSA-C22.2 No. 0.17.

5.3.4 A polymeric material used as an enclosure of a device marked for wet location use shall comply with the ultraviolet light exposure test specified in UL 746C or CAN/CSA-C22.2 No. 0.17.

5.3.5 With respect to UL 746C, the following tests are not required to be conducted:

a) The abnormal operation and severe conditions test,

b) The input after mold-stress relief distortion test, and

c) the volume resistivity test.

5.3.6 A device shall comply with the mold-stress relief distortion test of Clause 8.9.

5.3.7 A polymeric material used for direct support as electrical insulation shall be able to withstand the hot wire ignition (HWI), the comparative tracking index test (CTI), and the high current arc ignition (HAI) to a level of at least the values in accordance with Table 5.2.

Table 5.2

Ratings of polymeric materials

(See Clause 5.3.7)

| Environmental rating | Flammability classificationb | CTIc | HWId | HAIe | |||

|---|---|---|---|---|---|---|---|

| Minimum volts | PLCf | Minimum seconds | PLCf | Minimum seconds | PLCf | ||

| Dry location | 5-VA, 5-VB, V-0 | 100 | 4 | – | – | – | – |

| Damp location | 5-VA, 5-VB, V-0 | 175 | 3 | – | – | – | – |

| Wet location | 5-VA, 5-VB, V-0 | 250 | 2 | – | – | – | – |

| Any | 5-VA, 5-VB | – | – | 15 | 3 | 30 | 2 |

| Any | V-0, VTM-0 | – | – | 7 | 4 | 15 | 3 |

| a Enclosures of phenolic, urea, or other thermoset materials are acceptable as legacy materials. Thermoplastic materials shall comply with this table. First, the flammability classification is determined, and then CTI, HWI, and HAI requirements are determined as a function of the flammability classification. | |||||||

| b Flammability classification determined by prior classification or by 12-mm end-product (needle) flame test described in UL 746C or CAN/CSA-C22.2 No. 0.17. | |||||||

| c Comparative tracking index – Determined by prior classification or by end-product test described in UL 746C or CAN/CSA-C22.2 No. 0.17. | |||||||

| d Hot wire ignition – Determined by prior classification or by end-product test described in UL 746C or CAN/CSA-C22.2 No. 0.17. | |||||||

| e High-current arc resistance to ignition – Determined by prior classification or by end-product test described in UL 746C or CAN/CSA-C22.2 No. 0.17. | |||||||

| f For materials with other than VTM flammability classifications, the performance level class (PLC) for material shall be evaluated using the specimen thickness employed in the end product. PLCs have been established in order to give a consistent numbering for improved performance (PLC=0 is best; PLC=5 is poorest) and avoid an excessive level of implied precision. Material performances for several tests and recorded as PLC values are based on the mean test results rather than recording the exact numerical results. | |||||||

塑料外壳的RTI必须大于热测试结果;

wet location 的需要有F1材料等级;

塑料材料等级需要5-VA,5-VB,V-0;

若是塑料直接接触带电部件必须符合table 5.2 UL 1993 的要求。

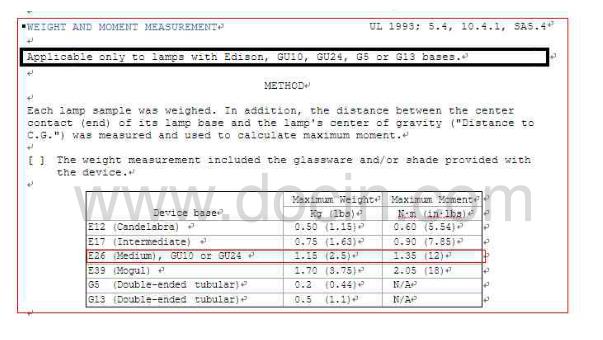

重量和力矩测试

重量满足Table 5.3 UL 1993的要求

Table 5.3

Weight and moment limitations

(See Clause 5.4.1)

| Device base | Maximum weight,a,c | Maximum moment,a,b |

|---|---|---|

| kg (lbs) | N�m (in-lbs) | |

| E12 (Candelabra) | 0.50 (1.15) | 0.60 (5.54) |

| E17 (Intermediate) | 0.75 (1.63) | 0.09 (7.85) |

| E26 (Medium), GU10, GU24 | 1.15 (2.5) | 1.35c (12) |

| E39 (Mogul) | 1.70 (3.75) | 2.05 (18) |

| a For weight and moment measurements, lamp adapters shall be provided with lamps. | ||

| b The moment is the weight of a device multiplied by the distance between the center contact of the device lamp base and the center of gravity of the device. | ||

| c Includes the weight of any glassware and/or shade provided with the device. See Clause 5.4.3. | ||

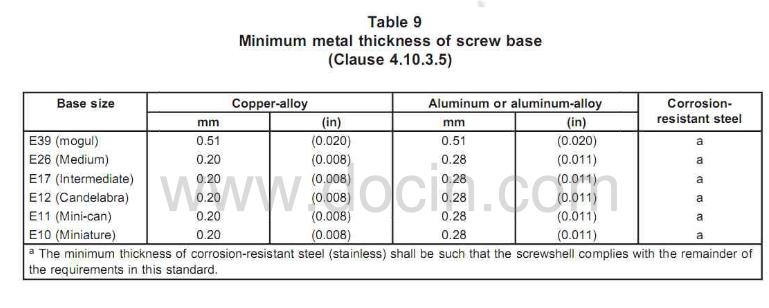

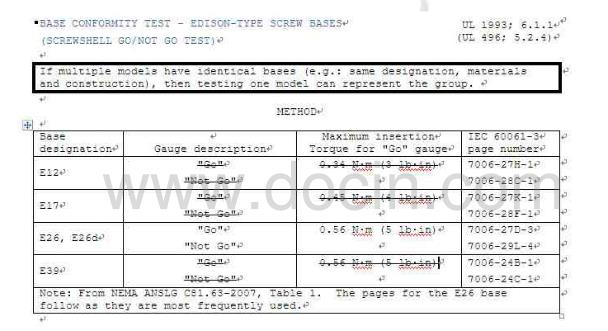

灯头量规和灯座

灯头和灯座符合UL 496 的要求

满足IEC 60061-1的标准尺寸

厚度满足Table 9 UL 496

灯头材质是铝或是铝合金不可以做灯头的材质

灯头和灯座

6.1.2 A screwshell metal of a device base shall be made from:

a) Copper alloy with a minimum of 80 percent copper,

b) Nickel alloy,

c) Stainless steel, or

d) Aluminum or copper alloy electroplated with nickel alloy covering all surfaces (after forming and trimming).

Unplated aluminum is acceptable as a screwbase metal only for devices intended for dry and damp locations.

载流部件

6.2.1 A wire shall have insulation rated for the voltage, temperature, and conditions of intended use.

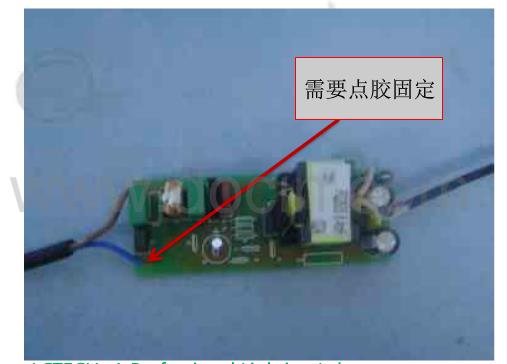

6.2.2 Where loosening or breaking of electrical connections involves a risk of fire or electric shock, the connections shall be soldered, welded, or otherwise securely connected. A soldered joint shall be mechanically secure before soldering. A surface mount component not exceeding a maximum dimension of 13 mm (0.5 in) need not comply with this requirement.

6.2.3 A wire is considered to be mechanically secure when one or more of the following is provided:

a) At least one full wrap around a terminal,

b) At least one right angle bend when passed through an eyelet or opening, except on printed-wiring boards where components are properly inserted and soldered or mechanically secured by design, or

c) It is twisted with other conductors.

6.2.4 Iron or steel, plain or plated, shall not be used for current-carrying parts unless it is a wire integral to the lamp light source or parts used for the containment of electromagnetic or electrostatic fields.

电气连接需要先机械固定

铁和钢不可以作为载流部件

内部线要在额定电压和温度下使用

CR&CL 要求

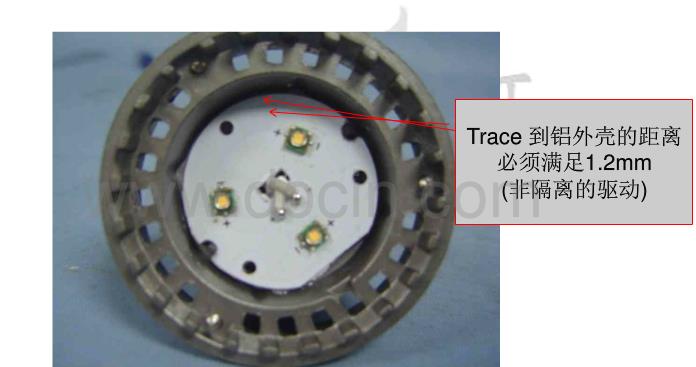

除了PWN/PCB 空气 a, 不同极性的带电部件, b: 带电部件和dead metal

Table 6.1 UL 1993 的要求:

Table 6.1

Minimum spacing, dry, damp, and wet locations

| Location Type | Potential, Va | Minimum spacing, mm (in) | |

|---|---|---|---|

| Through air or over surface | |||

| Dry or damp | 300 or less (425) | 1.2 | (0.046) |

| Dry or damp | 301 – 600 (426 – 846) | 3.2 | (0.125) |

| Wet | Less than 600 (848) | 4.8 | (0.187) |

| a The figures in parentheses are peak voltages. When evaluating the voltage of a circuit that produces other than sinusoidal waveform, both rms and peak values are evaluated and the requirement for the larger spacing shall be applied. | |||

例子:

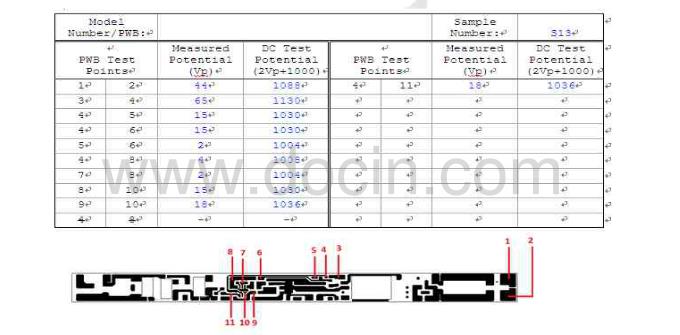

LED 驱动的CR&CL 要求

LED 驱动板的按照UL 8750 7.4 评估,假如有不足的地方可以通过高压来评估,再不行课可以通过短路来评估,开关电源内部通过table 7.6 评估。

OOLV 的测试

1,weight and monent measurement

2,base conformity test-edison-type screw bases

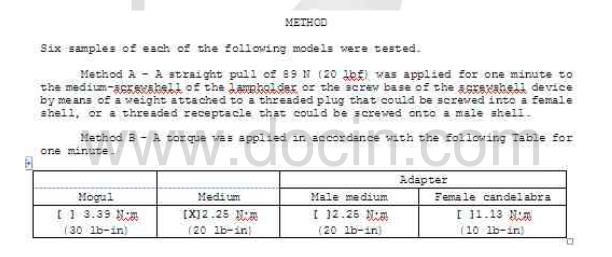

3, mechanical streangth of screwshell and scre base

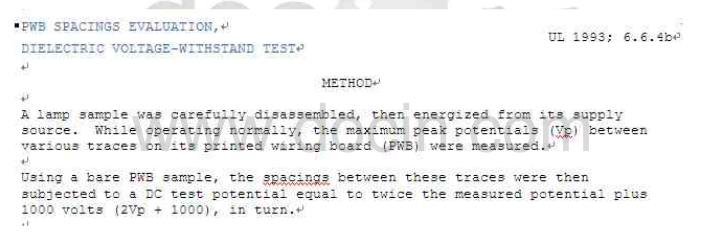

4, pwb spacings evaluation, dielectric voltage- withstand test

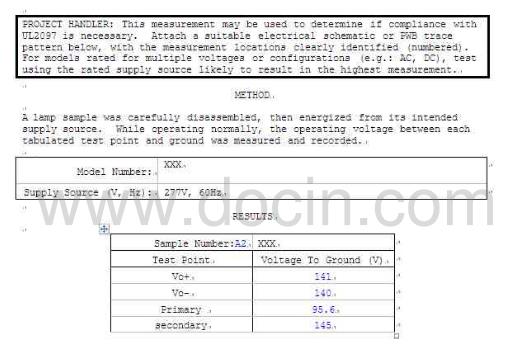

5,voltage to ground measurements

评估产品内部电压是否超过150Vac, 如超过需要符合UL 2097 的要求

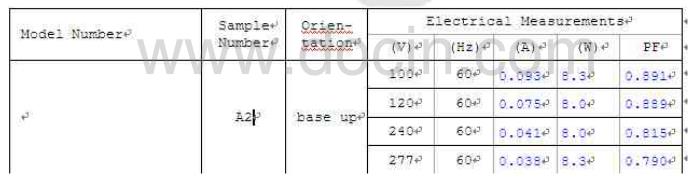

6, input measurements 额定电压稳定半个小时后,记录输入输出功率和电压,电流。

实测功率,电流不可以超过标称的1.1倍

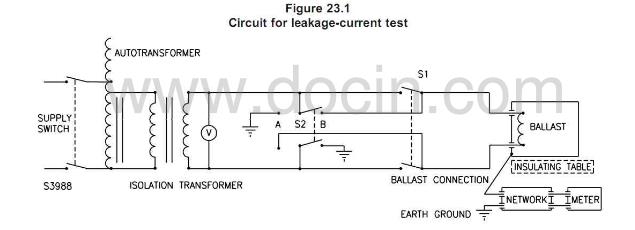

7, leakage current test

漏电流不能超过0.5 MIU

8, temperature test

9, dielectric voltage-withstand

金属外壳和输入1240 Vac, 1 min; 非金属外壳和输入2500 V, 1 min;

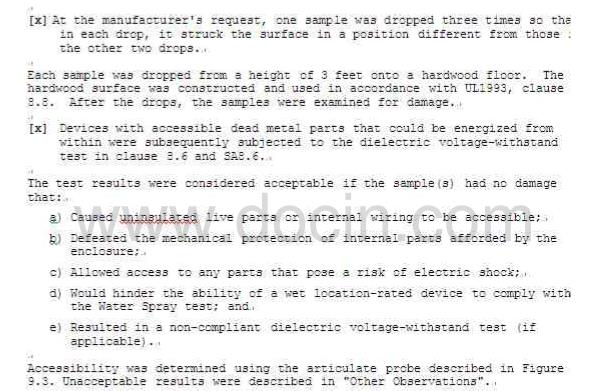

10, drop impact test

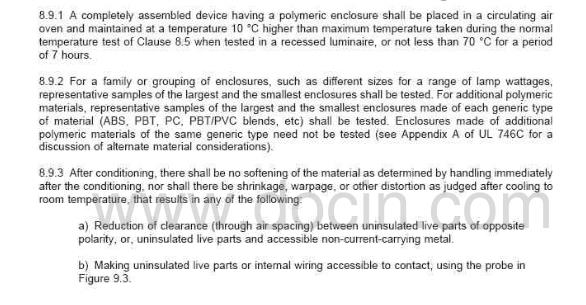

11, mold stress-relief conditioning

外壳是塑料材料需要进行这个测试,测试温度最低是70度,一般是比热测试高10度,塑料不可以影响正常使用

12, deflection test

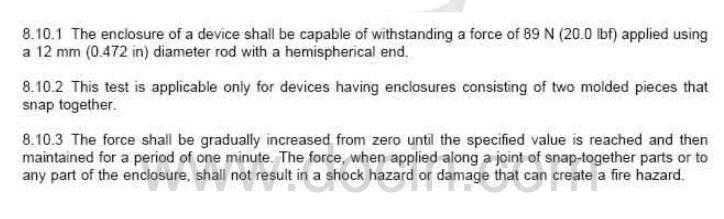

12 mm 直径,带半圆头金属棒,89 你, 1 min余连接处,判定没有带电部件外露,CR&CL不变

标准要求:

13, tests of dimmer circuits-abnormal

带调光电路的需要进行 Normal temperature

半波整流电路和可调光电路(参考温升8.5 UL 1993)

不带调光电路需要进行Abnormal Temperature

半波整流电路,可调光电路,工作7.5小时纱布,没有变形通过高压

14, humidity conditioning

Damp Location ,有可触及的金属载流部件,湿度93±2, 环境温度25±, 时间48H。通过高压测试

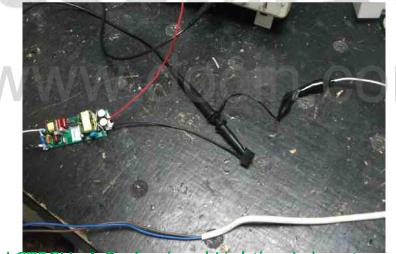

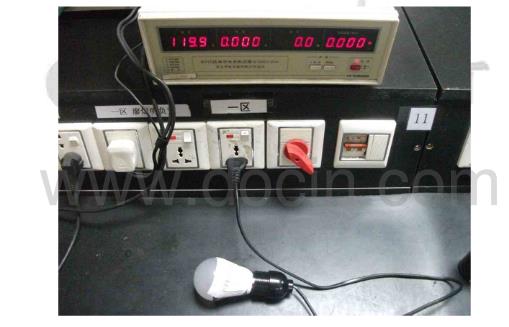

测试照片:

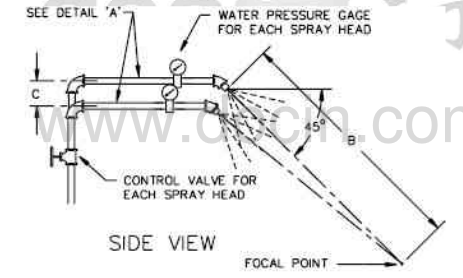

— Water Spray Test (可选,适用于Wet Location 灯泡)

淋雨测试可以按照客户的提供方向,如果不限制方向,base down 也是需要做测试,需要提供防水灯座。

UL 1993 要求:

防水设备:

Wet Location 的产品需要额外增加低温冲击进测试

-35±2, 3H, 做Drop Test.

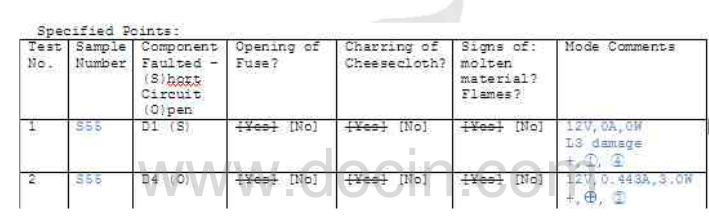

15, LED lamp driver abnormal condition test

短路描述

16, Adhesive support test

待续。。。

17, Determination of low-voltage limited energy circuit status

待续。。。

Marking

待续。。。。。